Blog

- Home

- Blog

How to Choose the Right Stainless Steel Woven Wire Mesh?

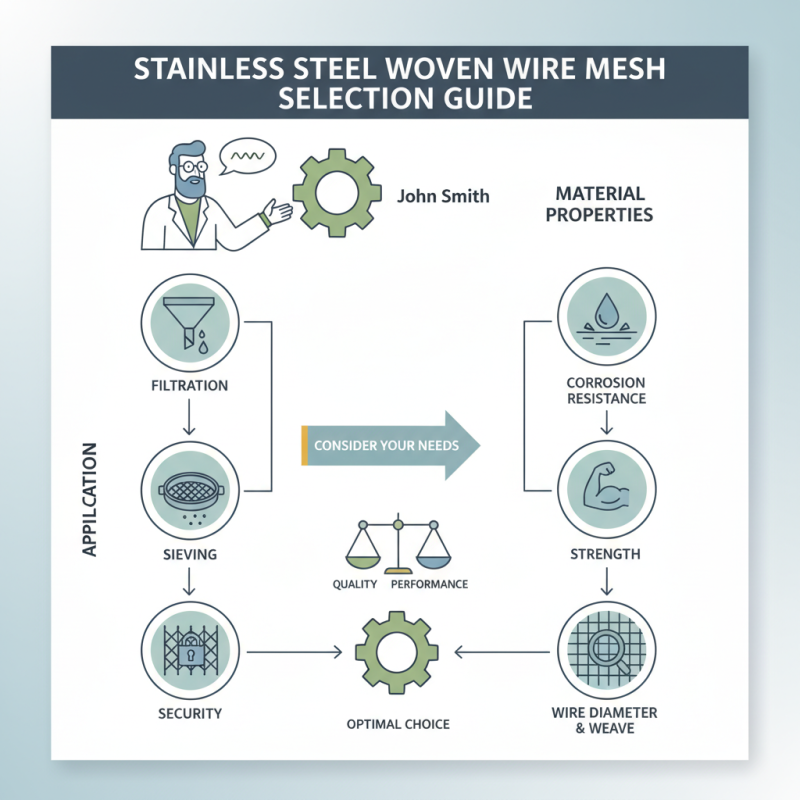

When it comes to choosing the right stainless steel woven wire mesh, the options can be overwhelming. Expert John Smith, a recognized authority in the industry, emphasizes, "Quality and application are key factors in selecting the right mesh." This statement reflects the importance of understanding both the material and its intended use.

stainless steel woven wire mesh serves various purposes, including filtration, sieving, and security. Each application dictates specific requirements, such as wire diameter and weave pattern. For example, a finer mesh may be required for filtration, while a sturdier option suits security fencing. The key is to find a product that aligns with your needs.

It's essential to consider the characteristics of different stainless steel grades. Factors such as corrosion resistance and strength will influence your decision. Reflecting on your specific needs is crucial. What works for one application may not suit another. Balancing these elements is vital for optimal performance.

Understanding the Basics of Stainless Steel Woven Wire Mesh Types

Choosing the right stainless steel woven wire mesh requires some understanding of its types. There are several key variations to consider. One common type is plain weave mesh, where wires cross at right angles. This type is often used for filtration and protection. Another type is twill weave, which creates a smoother surface. It is more flexible and often used in more demanding applications.

You might also come across Dutch weave mesh. This type has a tighter weave on one side. It is beneficial for separating fine particles. When selecting the right mesh, think about your specific needs. Consider factors like particle size, mechanical strength, and corrosion resistance. It’s important to assess the environment where the mesh will be used. Will it be exposed to chemicals? Will temperature fluctuations affect it? Reflect on these questions to avoid future issues.

Pay attention to the opening size and wire diameter. These aspects determine the mesh’s functionality. However, it can be tricky to find a balance. A finer mesh offers better filtration but may not handle heavy loads well. Conversely, a coarser mesh can support more weight but allow larger particles to pass through. Each choice has its pros and cons, requiring careful thought in your decision-making process.

Stainless Steel Woven Wire Mesh Types and Their Applications

Key Factors Influencing Stainless Steel Mesh Selection for Specific Applications

When selecting stainless steel woven wire mesh, several key factors play a pivotal role. The mesh's purpose significantly influences choice. For instance, filtration applications require finer mesh sizes. A tighter weave ensures particles do not escape. Conversely, a more robust mesh is suitable for strength-oriented tasks. Understanding these needs can shape your decision.

Material grades also matter. Different grades offer varying resistance to corrosion and heat. While some grades are ideal for food processing, others suit harsher environments. It’s crucial to match the mesh with its application. Consult with experts when unsure about material properties.

Mesh size and opening dimensions impact performance directly. Too large a gap might lead to product loss. Too small could slow processing speed. Testing different configurations can help find the sweet spot. Don’t hesitate to experiment with various options to see what works best. Sometimes, initial choices might not yield expected results. Adjusting and learning from those experiences is important.

Analyzing Stainless Steel Grades for Optimal Durability and Corrosion Resistance

Choosing the right stainless steel woven wire mesh requires careful consideration of the steel grades. Stainless steel is known for its durability and corrosion resistance, but not all grades offer the same level of protection. Often, people overlook the importance of selecting the right grade, leading to premature wear and tear.

Different stainless steel grades serve various purposes. For example, 304 stainless steel is common due to its balance of strength and corrosion resistance. However, if you need a mesh for harsher environments, consider 316 grade. It includes molybdenum, which enhances its resistance to pitting and chloride exposure. This choice can be critical for places like coastal areas.

Tip: Always assess your environment before making a decision. Look around for signs of corrosion in similar applications. It may save you time and money later.

Another aspect to explore is the wire thickness. A thicker wire mesh can provide better strength and durability, but it may affect airflow and visibility. Striking a balance is essential. Some applications require transparency, while others prioritize strength.

Tip: Test samples in your intended setting. This way, you can truly gauge how the mesh will perform in real-world conditions. Consider your priorities carefully.

Evaluating Wire Diameter and Weave Patterns in Woven Mesh Performance

Choosing the right stainless steel woven wire mesh involves a critical evaluation of wire diameter and weave patterns. These factors significantly influence performance and durability. For example, a thicker wire can increase strength but may reduce flexibility. Industry reports indicate that wire diameters of 0.20 mm to 2.00 mm are commonly used, with thicker wires often better for heavy-duty applications.

Weave patterns also play a vital role in performance. A plain weave offers a balanced combination of strength and flexibility, making it suitable for various applications. In contrast, a twill weave enhances the mesh's ability to filter smaller particles. However, it may also complicate cleaning processes. A recent study revealed that meshes with finer weaves can trap 30% more contaminants than coarser ones.

Evaluating the right choices is sometimes difficult. Different applications may require a trade-off between strength and filtration efficiency. It’s essential to consider the specific requirements of your project. Take time to assess how the wire diameter and weave pattern will align with your needs, as miscalculations can lead to performance issues down the line.

Industry Standards and Certifications for Quality in Stainless Steel Mesh Products

When selecting stainless steel woven wire mesh, industry standards and certifications play a crucial role. High-quality products often meet specifications like ASTM A480. This standard ensures the steel has the right thickness and finish for durability. According to a recent report by Smithers Pira, the global market for wire mesh is expected to grow by 5.1% annually until 2027. This trend emphasizes the importance of choosing certified products.

Tips for selection include checking certifications. Look for ISO 9001 certification. It indicates a commitment to quality management. Furthermore, ask suppliers about their compliance with ASTM standards. Not all products meet the same criteria. Quality can vary significantly, and some may not perform as expected.

Consider the mesh’s wire diameter and opening size. Smaller openings enhance filtration, while larger ones provide strength. The choice affects performance in various applications, from filtration to security. Understand the intended use of the mesh. Not all stainless steel is created equal. Some might corrode more quickly under certain conditions. Always require documentation that verifies the mesh meets industry standards.