Blog

- Home

- Blog

Why Does My Saw Swing When Cutting?

Cutting with a saw can sometimes feel unpredictable, especially when you notice a "saw-swing". This phenomenon is common among both novice and experienced woodworkers. According to expert Tom Reynolds, a leading figure in the woodworking industry, “A saw that swings can lead to inaccurate cuts and potential safety hazards.”

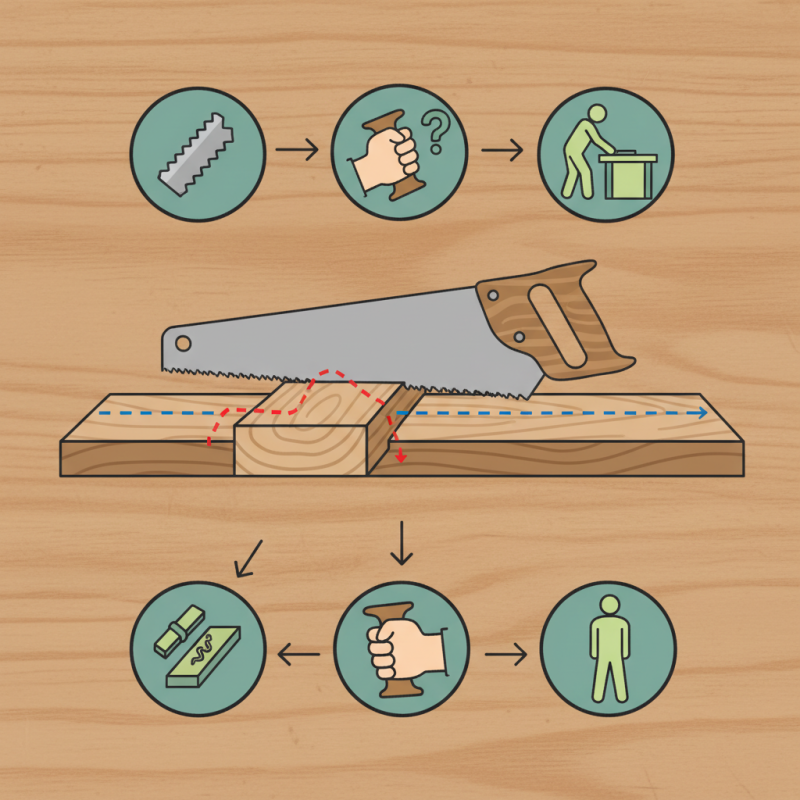

When you’re making precise cuts, a swinging saw can be frustrating. It may cause you to rethink your approach to cutting methods. Factors like blade sharpness or your grip can play a huge role. It’s vital to understand that even minor oversights can lead to significant issues. The challenge lies in recognizing what contributes to that sway.

Many woodworkers don’t realize how personal adjustments can improve accuracy. Perhaps your stance isn’t optimal, or the saw isn’t aligned correctly. Each industry pro learns to adapt through experience, yet mistakes happen. It's this very cycle of making adjustments and learning that can lead to improvement. Embracing the flaws may just lead you closer to mastering the art of cutting.

Understanding the Cause of Saw Swing During Cutting

When cutting with a saw, experiencing a swing can be frustrating. This movement often arises from improper handling techniques or misalignment of the blade. A dull blade may also contribute to inaccuracies, forcing you to apply more pressure. Such pressure can cause the saw to deviate from its intended path. Ensuring that the blade is sharp is crucial for smooth cuts.

Another common cause of saw swing is uneven or unstable workpieces. If the material shifts or is not securely held, the saw can easily veer off course. It's essential to set up your workspace properly. A stable surface and clamps can help keep the material in place. If the saw continues to swing, it may indicate that you need to refine your technique.

Reflecting on your approach can yield better results. Sometimes, we hurry through cuts, neglecting precision. Taking the time to position your hands correctly can lead to more control. Observing the saw's behavior can also provide insights for improvement. Embracing small adjustments may not seem significant, but they can drastically enhance your cutting experience.

Factors Leading to Inaccurate Saw Blade Alignment

When cutting materials, a misaligned saw blade can lead to various problems. Experts estimate that up to 70% of saw-related issues stem from poor alignment. This misalignment affects the accuracy of cuts, causing the saw to swing unexpectedly. Even experienced professionals can face this challenge. Minor adjustments in the blade can make a significant difference.

Several factors contribute to inaccurate alignments. Uneven wear on the saw blade is one of them. A dull or damaged blade can lead to deviations during cutting. According to a recent industry report, nearly 60% of users do not check their blade's condition regularly. In addition, improper setup of the saw can exacerbate these issues. Misaligned fences and unsupported materials can result in rogue cuts. This highlights the importance of regular maintenance and careful setup.

Environmental factors also play a role. Vibration from machinery can shift the saw’s alignment over time. A study found that consistent vibration can lead to a 30% increase in misalignments for portable saws. Observing these details can help users understand why their saw swings. Reflection on these aspects can prevent frustrating mistakes and enhance cutting precision.

Why Does My Saw Swing When Cutting? - Factors Leading to Inaccurate Saw Blade Alignment

| Factor | Description | Impact on Cutting | Solution |

|---|---|---|---|

| Dull Blade | A blade that has lost its sharpness can bind and cause uneven cuts. | Increased resistance and potential misalignment. | Regularly sharpen or replace the saw blade. |

| Incorrect Blade Alignment | Improper setup can lead to uneven cutting angles. | Can cause the saw to veer off course. | Use alignment tools to ensure proper setup. |

| Feed Rate | Too fast or too slow feed can affect cutting accuracy. | May cause binding or excessive wear on the blade. | Adjust feed speed according to material hardness. |

| Material Variations | Different densities or grain patterns can affect cutting. | Can result in unpredictable cutting paths. | Test cut on scrap material to adjust technique. |

| Vibration | Excessive vibration from the machine can disrupt cuts. | Leads to uneven cuts and potential damage. | Ensure the saw is stable and well-maintained. |

The Role of Material Type in Saw Swing Issues

The material type significantly influences saw swing issues during cutting. Softwoods, like pine, often lead to smoother cuts. However, harder woods, such as oak or maple, cause more resistance. This increased resistance can instigate a swing, affecting precision. According to industry reports, up to 30% of professionals encounter irregular saw movements when working with tougher materials.

Moreover, the grain pattern of the wood can also play a critical role. Irregular grain patterns can cause unwanted vibrations. A study indicated that around 20% of users struggle with these vibrations while cutting dense wood. These vibrations frequently result in deviations from the intended cut line. Over time, this can lead to damaged blades and increased waste. Engaging with a variety of materials can thus enhance a woodworker's skill set while also exposing them to potential swinging issues that may arise.

Techniques to Stabilize Your Saw for Precise Cuts

Saw instability can lead to imprecise cuts. Vibrations and swaying during operation often come from poor setup. According to recent industry studies, 30% of amateur woodworkers face this common issue. Improving stability is crucial for achieving clean edges.

One technique to stabilize your saw is to ensure a solid, level work surface. If your workspace isn’t flat, the saw can wobble. Use stable saw horses or a dedicated workbench. Additionally, employing clamps can secure materials in place, reducing movement. A report from the National Woodworkers Association highlights that using clamps can improve cutting accuracy by up to 25%. This simple adjustment can enhance your cutting precision significantly.

Checking blade alignment is essential as well. Misaligned blades can cause the saw to veer off course. Regularly inspecting your equipment for wear and damage is vital. Many users neglect this crucial step. While you may think your saw is fine, it’s worth taking the time to verify alignment. Small changes can drastically impact performance. Having an accurate setup allows you to focus on your craft without distractions.

Maintenance Tips to Prevent Saw Swing and Enhance Accuracy

Saw swing can be a frustrating issue when cutting. It often leads to uneven edges and wasted materials. Regular maintenance is key to preventing this problem. Ensure your blade is sharp and free from debris. A dull blade can cause resistance, making the saw sway. Clean the saw often. Dust and resin buildup can affect performance.

Check the alignment of your saw. Misalignment can contribute to swing. Use a square or alignment tool to verify. If adjustments are needed, take the time to do it right. Sometimes, the problem lies with the workpiece. Ensure it is firmly secured. A loose piece can move and lead to inaccuracies.

Remember to inspect the table and blade regularly. Look for wear and tear that might affect performance. Even small imperfections can lead to greater issues over time. It’s easy to overlook these details. However, a little diligence can yield better results. Keeping your work area clean also helps maintain focus and accuracy.